Want to take your operations to the next level?

Rugged devices are ideal for surveillance of processes to prevent errors, increasing manufacturing efficiency and freeing up staff to work on more complex issues. Both on the factory floor and in warehouses and logistics facilities. Our rugged devices are resistant to most stresses and can be freely placed next to concrete mixers, lathes, pumps and electrical welding equipment, as well as in component supply or shipping facilities. Forget expensive climate-controlled enclosures, our products handle the pressure in the harshest environments.

Reasons for choosing JLT in manufacturing

Increased efficiency and error prevention

Our rugged devices are ideal for surveillance of processes to prevent errors, increasing manufacturing efficiency and freeing up staff to work on more complex issues on the factory floor or in the warehouse.

Heated display for extreme cold

Our rugged JLT1214N computer with automatic heater on the front prevents frost formation in drastic temperature changes, for example when going in and out of a blast freezer storage.

Built for the toughest environments

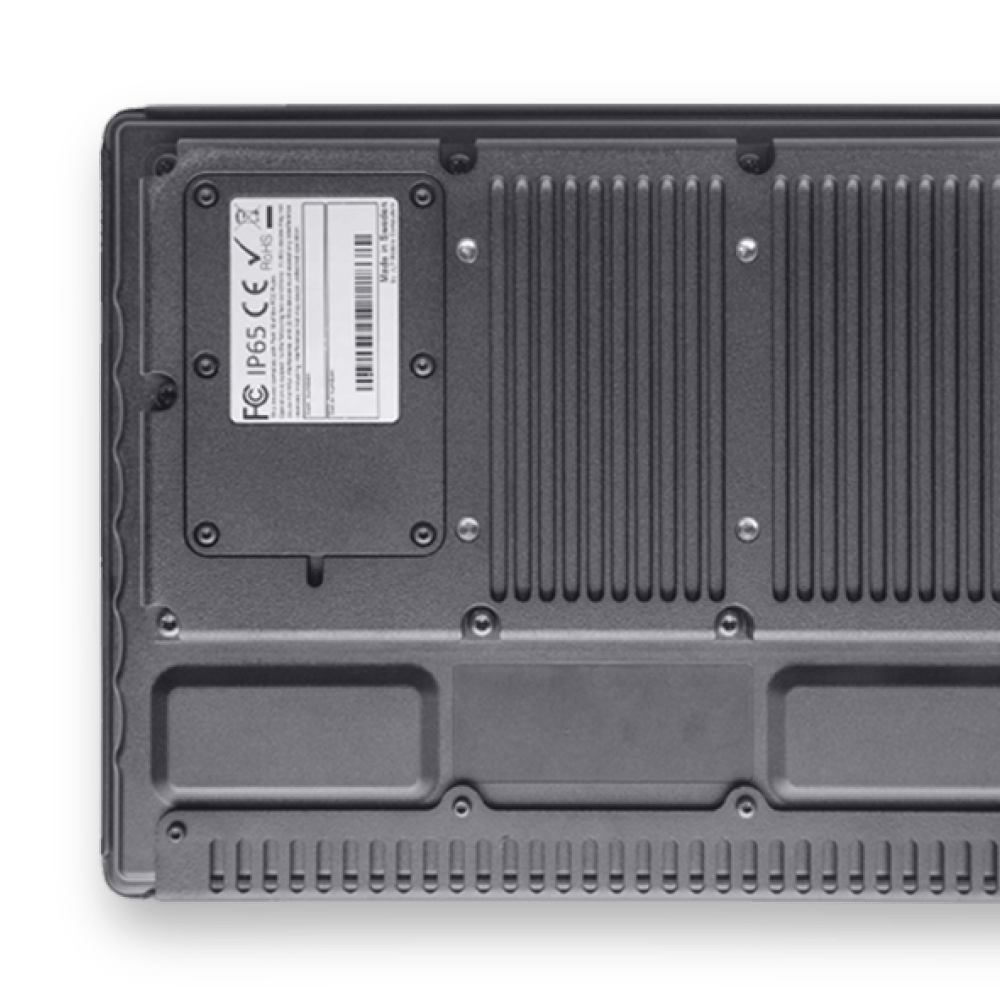

All of our products withstand significant temperature changes, severe vibrations, are IP65 or IP66 dust-resistant and waterproof, and come in a compact format, making them ideal for use in the manufacturing industry.

Explore our products and services

Vehicle-mount computers

Tablets & handhelds

Software

Have a question?

We’re here to help and advise you on every aspect of rugged devices and industry data communications.

Please fill in the form and we will get back to you as soon as possible.

Manufacturing and industrial automation

Being able to place devices anywhere that automation or information is needed opens up many possibilities. For example, much time and effort can be saved by controlling several machines through a common interface. Rugged devices are ideal for surveillance of processes to prevent errors, increasing manufacturing efficiency and freeing up staff to work on more complex issues. Both on the factory floor and in warehouses and logistics facilities.

An efficient supply chain

Getting the right goods to the right recipient at the right time is an ongoing challenge. Traceability is key, which means managing business-critical information reliably throughout the supply chain. Demanding environments and tight regulations place special demands on data-handling equipment, and JLT rugged devices are perfectly suited to these challenges.

Making it work

Manufacturing environments are often a challenge for data communications. Consistent coverage can be difficult to achieve, and there may be legacy systems to work around. We have the know-how to optimize your setup, working around physical limitations and managing system integrations to ensure you have the system to meet your needs.